Thought leadership

Where AI Delivers the Most Value in Logistics

Artificial intelligence has quickly shifted from being a technology discussion to a practical tool reshaping how freight is moved, monitored and managed. What once relied on manual decision-making, experience, and human interpretation is now supported by automation, predictive analytics, and intelligent optimisation. AI is not replacing logistics capability; it is enhancing it. In the right environment, it delivers better visibility, faster response times, improved cost control, and a more stable supply chain.

AI is no longer a future concept. It is now a practical part of high-performing freight networks.

How AI Fits into Modern Freight Operations

AI in logistics refers to systems that learn from data, recognise patterns and make decisions that improve operational outcomes. Unlike traditional logistics models that rely heavily on manual effort, AI evaluates information in real time and adapts dynamically.

AI helps logistics teams:

- automate repetitive or rules-based tasks

- improve forecasting and decision quality

- detect inefficiencies before they escalate

- optimise routing and service allocation

- reduce dependency on manual planning

The result is simpler decision-making, fewer errors and a supply chain that responds faster when conditions change.

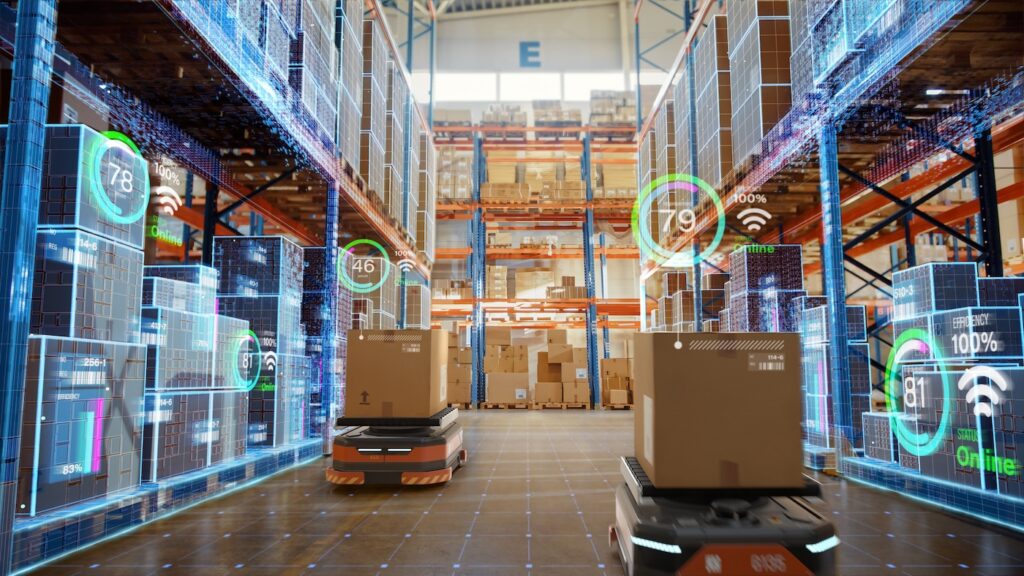

AI in the Warehouse

Warehousing has become one of the fastest-evolving parts of the supply chain, with AI at its centre. Intelligent systems and robotics now assist with tasks previously dependent on labour and human speed.

AI-enabled warehousing supports:

- faster and more accurate picking and inventory handling

- better visibility of stock movement and utilisation

- proactive replenishment and storage planning

- lower labour cost through automation of repeat work

Robotics, scanners and machine vision systems can verify orders, move stock, flag discrepancies and track performance without slowing activity. People still play a critical role, but work shifts from repetitive physical tasks toward supervision, quality control and exception handling.

AI for Routing and Transport Optimisation

Transport route planning has historically depended on dispatcher knowledge and manual evaluation. AI changes that by analysing thousands of data points simultaneously, such as traffic flow, weather conditions, delivery windows, vehicle capacity, freight profile and prior performance outcomes.

AI-driven routing can:

- shorten delivery paths to reduce fuel and distance

- minimise idle or empty vehicle movement

- improve DIFOT stability through better planning

- lower operational cost by reducing run time and resource usage

Better routing also improves fleet utilisation and reduces stress on last-mile capacity. Instead of reacting to congestion or delay events after they occur, AI helps avoid them before they form.

Predictive Analytics and Risk Reduction

Predictive analytics represents one of the most powerful and commercially valuable outcomes of AI. Rather than waiting for disruption, predictive systems use real-time and historical data to forecast potential problems, such as:

- volume spikes or inventory shortages

- bottlenecks in peak periods

- probable late delivery events

- price and cost fluctuations

This level of insight enables earlier intervention. Volumes can be rebalanced, carriers switched, capacity increased, or service allocation rules updated before failures begin affecting the customer. AI helps logistics teams move from reactive to proactive.

Autonomous Equipment and Network Visibility

Autonomous vehicles and equipment are advancing rapidly in controlled environments, particularly at depots, ports and warehouses. While full linehaul automation is still developing globally, semi-autonomous movement and dock handling are already demonstrating efficiency gains, safety improvement and lower handling costs.

The more immediate value for most businesses, however, is AI-powered visibility. Real-time tracking, predictive ETAs, milestone accuracy and automated exception alerts improve communication, reduce inbound inquiry traffic and build confidence across the supply chain.

Visibility does not eliminate problems. It shortens response time and improves the likelihood of a positive customer outcome.

The Commercial Value of AI in Freight Management

When embedded into the freight network with purpose, AI lifts business performance across multiple dimensions.

AI strengthens:

- delivery reliability and consistency

- cost efficiency across modes and lanes

- warehouse and picking accuracy

- exception awareness and response speed

- customer communication and trust

Businesses see the benefits most clearly when volume increases or networks become more complex. AI scales without requiring equivalent growth in headcount or overhead.

Where AI Creates the Greatest Advantage

AI delivers the highest returns when used not as a tool on the side, but as part of an integrated freight management approach. AI works best when paired with strong data, transparent processes, and carrier alignment.

The most significant uplift occurs when businesses:

- layer AI on top of high-quality operational data

- automate decisions that were previously manual and repetitive

- use analytics to reset network design and transport methodology

- integrate continuous improvement into freight governance

AI does not make a weak freight process strong. It makes a strong freight process more powerful.

The Bottom Line

AI has become one of the most meaningful developments in freight management. It reduces manual workload, improves decision accuracy, enhances visibility and helps networks perform at a higher level with fewer resources. The businesses that stand to gain the most from AI are not waiting for the technology to be perfect. They are using it to improve how they ship today, while preparing for even greater capability tomorrow.

AI is here. The advantage is in how you apply it.

FAQS

What is AI’s role in logistics and freight management?

AI streamlines logistics operations by automating tasks, optimising routes, and improving warehouse efficiency.

How does AI improve safety in logistics?

AI-powered systems like ADAS detect hazards, monitor driver behaviour, and prevent accidents in real time.

What are the benefits of AI for warehouse automation?

AI enhances warehouse efficiency by automating tasks, reducing errors, and optimising inventory management.

How does predictive analytics help in logistics?

Predictive analytics anticipates demand patterns and disruptions, enabling companies to optimise inventory levels and streamline operations.

What are future trends in AI and logistics?

Key trends include autonomous vehicles, enhanced predictive analytics, and AI-driven decision-making tools.